Die Casting Pipe

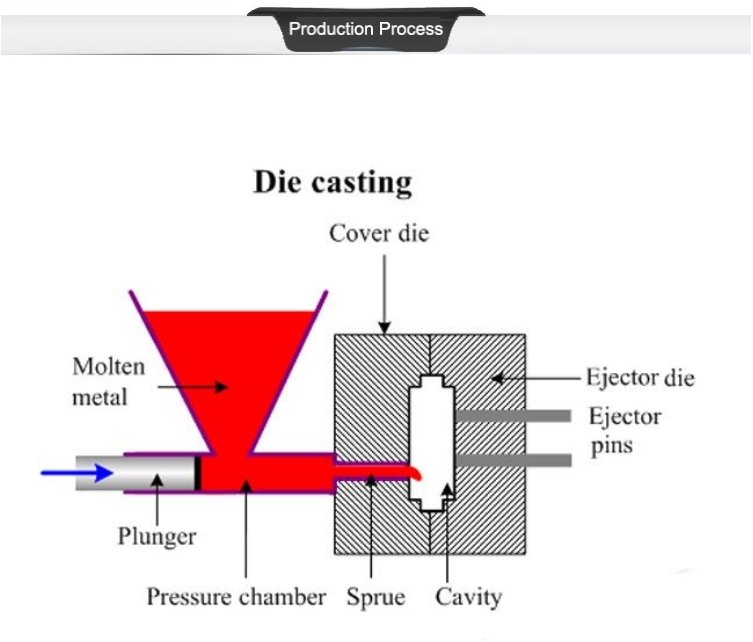

What is die casting process ?

Die casting is a metal casting process that involves feeding molten nonferrous alloys into dies under high pressure and at high speed to rapidly create molded products. The main materials used in die casting are alloys of aluminum, magnesium and zinc.

Advantages

Advantages of Die Casting:

Short Lead Time: A typical casting cycle of a die casting process is very short. In fact, depending on size and material

properties, it can be as low as a few seconds only.

Economical: Die casting is very economical for large batches of production. With time, the cost per part becomes surprisingly low.

Good Mechanical Properties: While not as strong as forged parts, die casting yields excellent mechanical strength. It can yield parts with enhanced durability, hardness, and conductivity as well.

Complex Details: You can manufacture complex parts in a very short period with die casting.

Excellent Precision: Die casting offers tighter tolerances than most other manufacturing techniques. Thus, it is suitable for many delicate applications.

Superior Finishing: You can design Die casting parts to have a smooth or textured finishing according to your requirements.

Layout

Request information

Fill out the online form to be contacted by a salesperson